Pressure Blasting Technology / Blasting cabinets

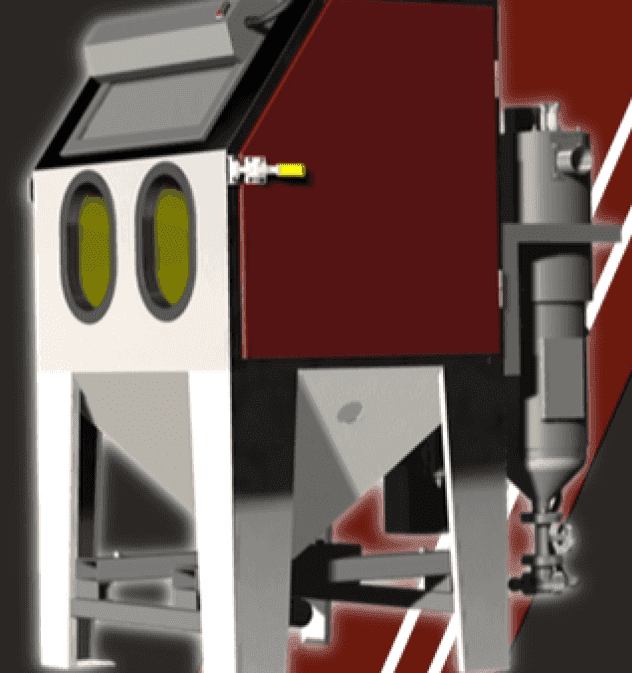

Our powerful pressure blasting systems consist of a robust steel construction and are equipped with cross beams and hollow supports for an easy and fast pick-up & relocation by means of lift truck, electric ant or fork lift truck.

The two generous swing doors on the right and left allow easy loading and unloading of your workpieces.

An interior brightly illuminated with LED lighting ensures good visibility, the two large, oval glove ports provide freedom of movement.

All blasting units are equipped with a suction slot that extends across the entire width of the rear wall. This ensures a laminar air flow and good visibility inside the blasting system.

Our Blasting cabinets in pressure blasting technology can be operated with all common blasting media. We would only recommend the compact RDP variant for heavy blasting media, such as stainless steel, as there is then no danger of the blasting media accumulating in the corrugated pipe lines.

Our pressure blasting systems can be operated from 1 bar air pressure.

With the purchase of our blasting systems, the initial filling of the blasting media that is right for your application is included in the price.

It goes without saying that we offer maintenance flat rates and service contracts for our systems, spare parts are in stock.