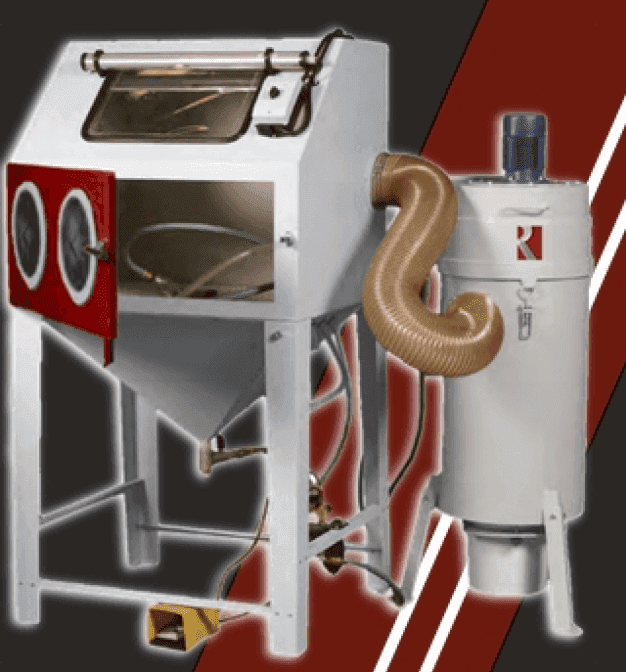

Injection blasting system RSC

Small front loader injection blasting system, incl. filter unit, working area W 890 x D 750 x H 760 mm, door opening W 775 x H 330 mm

In our Injection blasting systems we distinguish between the RSC or R1000 blasting system and the RDI and RFI series.

The RSC and R1000 blasting system is particularly suitable for occasional use as well as small or light workpieces.

The RDI and RFI series is very well suited for frequent, daily use as well as for heavy and large components, in particular due to the additional equipment variants.

When you buy our blasting machines, the initial filling of the right abrasive for your application is included in the price.

It goes without saying that we offer maintenance packages and service contracts for our systems, spare parts are in stock.